Step 1: Your Idea

You discovered a brilliant idea for your product, and now it’s our turn to transform your plan into reality. Tech-Way Industries understands that every product, project, company, and inventor is different, so we offer many flexible services around product design, engineering, prototyping, and manufacturing to fit your needs. We offer a free consultation to help you decide which services will achieve your goals and walk you through each step.

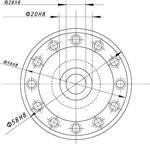

Step 2: Part Design

We have the resources through our partner design firm to help you with your 2-D and solid model (3-D) part design, helping you achieve the best part design for injection molding –taking into consideration proper draft angles, ejector pin locations, and gate locations. We use the Design for Manufacturability (DFM) process as we design your product. DFM is a cross-functional way to ensure unnecessary costs are not embedded in the design. We will consider the number of parts manufactured, the material used, the complexity of the surfaces, the tolerances required, and whether secondary processing is needed.

Step 3: Rapid Prototype Parts

See your idea begin to come to life with the fabrication of functional prototypes, scale models, short run production, and visual prototypes. Our engineers can build your prototype based entirely around how you plan on using it. Rapid prototyping services allow you to test a part while still in the design phase—saving you time and money by validating the part’s form, fit, and function before moving on to production. Our in-house rapid prototype approach includes machining, fuse deposition (SLA), and low-cost tools for functional prototypes, scale models, short-term production, and visual prototypes.

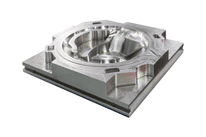

Step 4: Tool Design

We collaborate closely with each customer to ensure that your mold will produce parts that meet your exact needs. Precision, repeatability, and cost-effectiveness are the key focuses of everything we manufacture. We provide custom tool design or can fine-tune existing designs. Our tool designers create custom molds, runners, tooling, and fixtures for virtually any plastic molding method and for part sizes ranging from micro-components to oversized parts.

Step 5: Tool Design

After the design process is complete, the tool is built to the design specification and then tested. Our in-house tooling engineers ensure that the injection molds we build for you will be built to your print’s specifications and tolerances. We will build your tools based on your tooling cost, material, and life-of-tool requirements to ensure the quality of the part.

Step 6: Injection Molding

With your idea now a reality, your concept is now ready for production. Post molding, we also offer numerous secondary services such as finishing, machining, and part decorating services. Tech-Way industries offers a range of value-added finishing services including painting, texturizing, coating, and plating. We can assemble, package, warehouse, and ship your final product.

Contact us today to speak to a lead engineer about a free estimate and discover your product’s potential!

Step 7: Final Product

Equipped with cutting-edge manufacturing systems that provide injection, rotary overmolding, insert overmolding, multi-material, two-stage, gas assisted, and solid molding processes, our vast capabilities support the manufacturing of micro parts, miniatures, small parts, large parts, and multiple component assemblies.