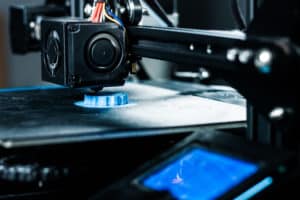

Tech-Way Industries provides outstanding rapid prototyping services to diverse industries, adhering to stringent regulations and meeting their high standards. As one of the top rapid prototyping companies, we utilize cutting-edge machines and tools to produce prototypes that can support your projects and drive success to your bottom line.

The Importance of Rapid Prototyping

Our rapid prototyping service revolves around ensuring that a product, part, or component is developed to the exact specifications and requirements of our clients. It’s a crucial part of product development since it saves time and money before mass production begins.

At Tech-Way, we specialize in CNC rapid prototyping and injection molding, two of the most widely used rapid prototype services. Below are some reasons why rapid prototyping is essential:

- Transform an idea or concept into a test subject

- Versatility in materials used

- Cost-effective way to test and evaluate designs

- Faster production time compared to traditional methods

- Allows for adjustments and improvements before mass production

- Reduces the risk of errors or flaws in the final product

What is CNC Rapid Prototyping?

As aforementioned, we focus on CNC rapid prototyping, which utilizes a CNC (Computer Numerical Control) machine to create a prototype from a digital design that’s produced through a CAD software. This method allows for precise and accurate production of complex shapes and geometries, making it ideal for producing intricate parts with tight tolerances.

Some reasons why you should consider CNC rapid prototyping include:

- Speed and accuracy: CNC machines can deliver exceptional accuracy because they’re fully automated. It eliminates the human error factor, improving the prototype’s overall design. The prototype can be made quickly because of the machine’s fast set-up and processing time.

- Easy modification: CNC machining allows for easy adjustments and changes since these machines can create the prototype in hours instead of days. In addition, a simple change in the program enables engineers to test several iterations without wasting time.

- Diverse materials: CNC machines can work with various materials, such as metals and plastics. It also handles difficult-to-machine engineering materials, such as Titanium and Inconel.

- Affordable: CNC machining is cheaper than other manufacturing techniques because it doesn’t require additional tooling.

Applications of Rapid Prototyping

Various industries rely on our rapid prototyping service to ensure that their desired products are developed to perfection and function according to their intended purpose. Some of the industries that benefit from our rapid prototype services include:

- Automotive: Dashboard, engine parts, and mechanical components.

- Aerospace: Turbine blades, cabin interiors, and brackets.

- Consumer Goods: Household appliances, electronic devices, and toys.

- Consumer Electronics: Smartphones, laptops, and other electronic devices.

- Medical and Healthcare: Customized prosthetics, surgical instruments, and medical equipment.

- Industrial Equipment: Machine parts, tools, and heavy equipment.

Let Tech-Way Manage Your Rapid Prototyping Projects

Rapid prototyping has become an integral part of the product development process due to the growing need for close-to-perfect products and components. At Tech-Way Industries, we understand the importance of delivering superior-quality prototypes on time and within budget.

Contact us today to learn more about our capabilities and how we can support your rapid prototyping needs. Request a free consultation so we can jumpstart your project with ease and confidence!

Rapid Prototyping Capabilities

- General Capabilities

-

Functional Prototypes

Scale Models

Short Run Production

Visual Prototypes

- Rapid Prototype Method

-

Machining

Fuse Deposition (SLA)

Low Cost Tooling

- Prototyped Product

-

Assembly Tools

Disassembly Tools

Weapon Components

Industrial Dish Washers

Blenders

Marking/Scanning Guns

- Materials

-

ABS Plastic

Aluminum

Pre Hard Steel

- Finish

-

Chemical Dipped

- Length

-

Up to 8 in.

- Width

-

Up to 8 in.

- Height

-

Up to 12 in.

- Layer Thickness

-

.007 in.

- Tolerance

-

± .002 in.

- Finishing

-

Automated Paint Line

Water-Based Paints

Water-Based Metallic Paints

Parts Decorating

Spatter Coating

Texturing

Plating

Coating

Powder Coating

Pad Printing (Including Metallic)

- Additional Services

-

Assembly

Packaging

Shipping

Warehousing

- Inspection

-

Coordinate Measuring Machine (CMM)

Video Probe Microscope

Optical Comparators

Micrometers

Calipers

Gage Blocks

- Testing

-

Leak

- Documentation

-

Procedure Sheets

Visual Plaques

PPAP

Certificate of Conformance (C of C)

First Article

- Quality Assurance

-

Advanced Quality Planning

Continual Quality Control

Customer Specification

- Production Volume

-

Prototype to Large Scale Production

- Typical Lead Time

-

3 to 4 weeks

In-House Customer Inventory Stocking

Just In Time (JIT) Delivery

Kanban

Additional Information

- Industry Focus

-

Medical

Pharmaceutical

Aerospace

Appliance

Defense

Electronic

Precision Optics

Oil Recovery

Alternative Energy

Automotive

Industrial

Firearms

- Intended Applications

-

Tooling

Molding

Optical Scanner Guns

- Industry Standards

-

ISO 9001:2015 Compliant

UL Certified

FDA Certified

- Efficiency

-

Six Sigma (Black Belt)

LEAN Manufacturing

Lights Out Manufacturing

- File Formats

-

SolidWorks

STEP203 / STEP214 (STP)

Unigraphics (PRT)

Parametric Solid (SMT)

IGES (IGS)

AutoCAD (DWG, DXF)

Kubotek KeyCreator