Services & Capabilities

- Product Development Support,

Engineering & ConsultingFrom design-for-manufacturability and prototyping, to comprehensive project management and reverse engineering design--we partner with you to accomplish your goals.

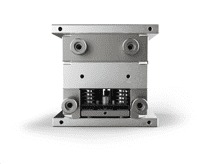

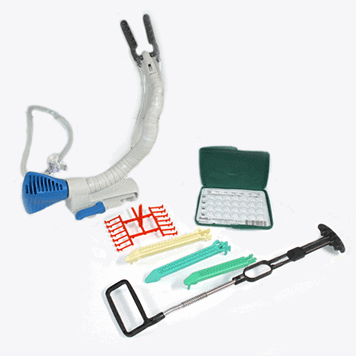

Learn More - Plastic Injection Molding

Our facility is equipped with cutting edge manufacturing systems that can provide injection, rotary, overmolding, insert, multi-material, two-stage, gas assisted, and solid molding processes.

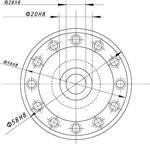

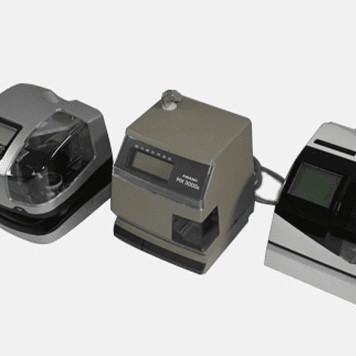

Learn More - Custom Plastic Machining

Tech-Way provides high-precision machining of a wide range of plastics and metals.

Learn More - Laser Engraving & Marking

Tech-Way engraves barcodes, serial numbers, logos, artwork and more.

Learn More - Clean Room Production

From tooling & molding to assembly & packaging, Tech-Way is your one source for clean room needs.

Learn More - Assembly & Packaging

Tech-Way performs assembly and packaging to help shorten your supply chain.

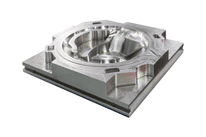

Learn More - Tooling & Mold Building/Development

Tech-Way is your source for custom molds, runners, tooling, fixtures, and more.

Learn More - Rapid Prototyping Services

Tech-Way quickly brings your idea to life with our Rapid Prototyping Services.

Learn More - Additional Services

Molding U.L. Certified parts and more, check out all the services Tech-Way has to offer.

Learn More

Concept to Creation

We have the resources to help you achieve your goals. We can partner with you to bring your product to life.

Learn MoreFirearm Components

You can join our list of long-term, satisfied clients for your firearm manufacturing needs.

Learn MoreClean Room Services

About Us

Always listening to our customers needs and staying on top of industry trends, Tech-Way can partner with you to make your ideas come to life.

ISO 9001:2015

ISO 9001:2015

Licensed Type 07 FFL Manufacturer

Licensed Type 07 FFL Manufacturer  ITAR certified

Learn More About Us

ITAR certified

Learn More About Us